Power Converter Repaired!

Printed From: R-pod Owners Forum

Category: R-pod Discussion Forums

Forum Name: Podmods, Maintenance, Tips and Tricks

Forum Discription: Ask maintenance questions, share your podmods (modifications) and helpful tips

URL: http://www.rpod-owners.com/forum_posts.asp?TID=14215

Printed Date: 13 Jul 2025 at 6:47pm

Software Version: Web Wiz Forums 9.64 - http://www.webwizforums.com

Topic: Power Converter Repaired!

Posted By: kickhead70

Subject: Power Converter Repaired!

Date Posted: 14 Nov 2020 at 2:24pm

|

Hello fellow podders! Quite happy this morning after a successful repair of my failed power converter. First notice I had that it went bad was a dead battery that was only a few months old. Converter was not charging the battery while on shore power. Eventually, nothing worked except outlets that were directly connected to shore power. I was able to pull the converter from under the power center and saw that the bottom of the enclosure was partially broken, the converter was not screwed into the enclosure, and the 15amp breaker to the converter was quite loose. One, or all, of the following restored functionality:

Reconnected all wires in the power center and plugged into shore power, fan came on and multimeter verified charging output! Yay! Sorry for lack of progress photos on this write up, but I wasn’t sure it would work. ------------- Wrangler Unlimitied 75th Anniv. Ed. 2017 R-Pod RP180 |

Replies:

Posted By: mcarter

Date Posted: 14 Nov 2020 at 4:26pm

|

THANKS for post, good job and write up. ------------- Mike Carter 2015 178 " I had the right to remain silent, I just didn't have the ability." |

Posted By: offgrid

Date Posted: 14 Nov 2020 at 6:13pm

|

Great fix, nice to see someone unafraid to tackle circuit board repair, kinda a lost art these days. thanks for the post! ------------- 1994 Chinook Concourse 1995 RV6A Experimental Aircraft 2015 Rpod 179 - sold |

Posted By: jato

Date Posted: 14 Nov 2020 at 8:57pm

I now know where to go if I have a similar problem. Never been to Livermore (yet). Great job and repair! Great job and repair!------------- God's pod '11 model 177 '17 Ford F-150 4WD 3.5 Ecoboost Jim and Diane by beautiful Torch Lake "...and you will know the Truth and the Truth will set you free." |

Posted By: Gebaldwin1

Date Posted: 15 Nov 2020 at 7:37am

|

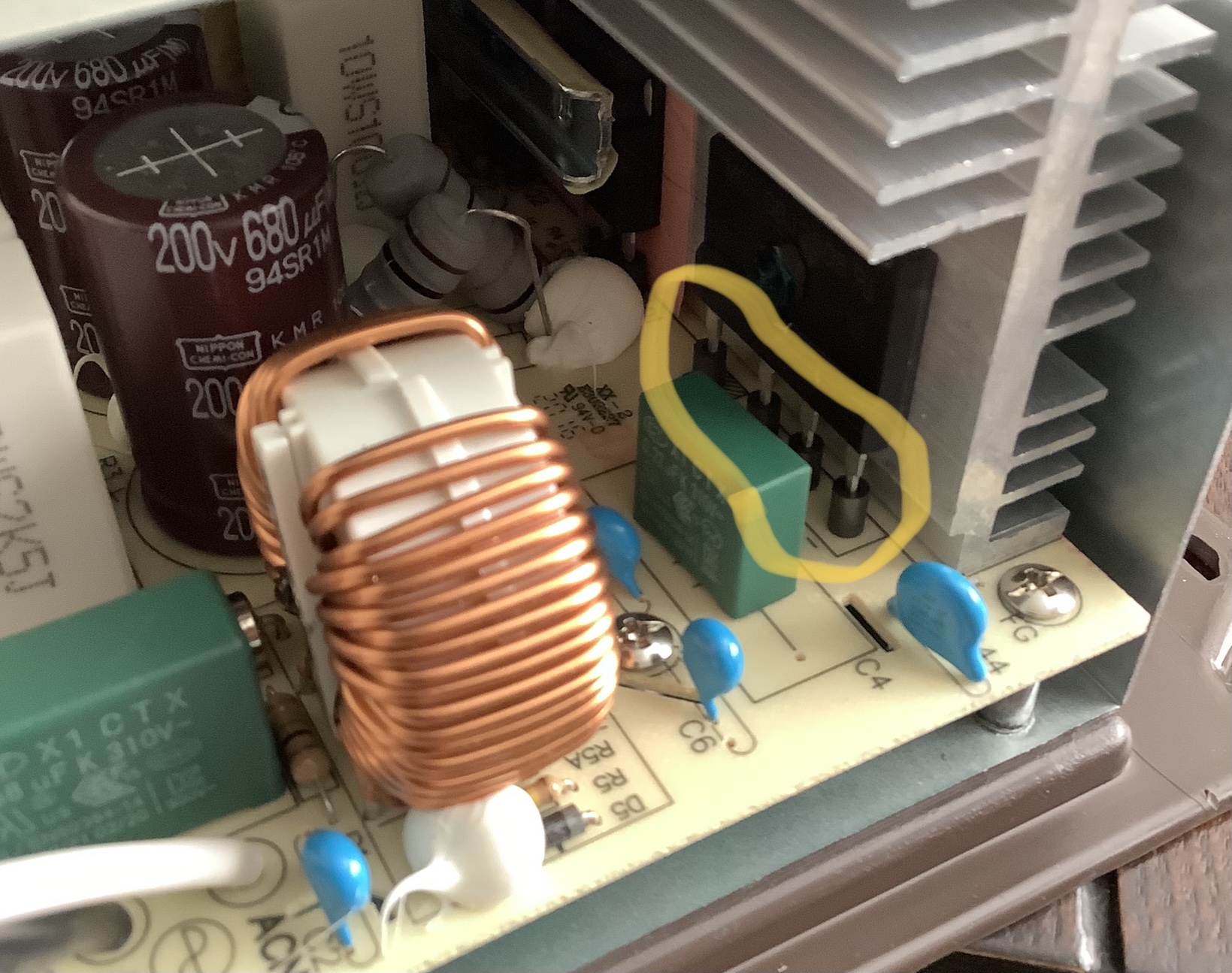

That "daughter" board that sticks up from the main board is most often the problem. It's terrible design to have that unsupported board in a device that sees significant bouncing & vibration in small travel trailers. The support of the enclosure is a good start - recommend also that you take a piece of popsicle stick and use a small dab of RTV silicone adhesive to brace the top edge of the daughter board to the enclosure to prevent if from wiggling loose again. ------------- GMan Lil' Bumpy - RPod 180 |

Posted By: kickhead70

Date Posted: 15 Nov 2020 at 11:17am

|

By daughter board, I think you’re referring to is the smaller circuit board the is perpendicular to the main board. That board is quite light, and even with road vibrations, wouldn’t really create much stress at the connection, IMO. My main problem is with the heat sink (aluminum with fins that’s vertical from the circuit board), that part needs a little more solid of a connection. In my case, that part had enough mass that during road travel, it created lots of deflection at its connection to the main board, and worked on the soldered connections. I’d contemplated trying to attach a brace of some kind, but hoping that re-securing the other connections will be good enough. If I have to get in there again, I’ll take a look for what you’re suggesting, thanks! ------------- Wrangler Unlimitied 75th Anniv. Ed. 2017 R-Pod RP180 |